By Jacob Jenkins, science & technology reporter

After a year of design and preparation, the Virginia Tech Motorsports Formula SAE team is currently in the process of manufacturing their vehicle for the 2026 competition year. The student design team will soon face off against 120 teams nationally to try and prove their vehicle ranks highest in regard to dynamic ability, superior design, and reliable technology.

The Virginia Tech Formula team, which is based at the school’s Ware Lab, has been competing in Formula SAE (Society of Automotive Engineers) competitions since 1985, which offers an incredible hands-on learning experience. Students across majors are tasked with designing, manufacturing, and racing a small formula-style race car. The Virginia Tech Formula team has consistently delivered since its conception, establishing itself as a powerhouse nationally. A strong performance last year earned the team 15th place in the ‘25 competition. With three months until the ‘26 competition, it is officially crunch time for the team as they ramp up their building phase in pursuit of first place.

What many might not know is just how much work goes into planning and developing a miniature race car. Eighty engineers and 10 business leaders work diligently throughout the school year to ensure final products will perform at competition and amplify Virginia Tech’s status as a premier team. There are strict timelines, various sub-teams, funding needs, and interdisciplinary work that make for a complicated and rigorous process.

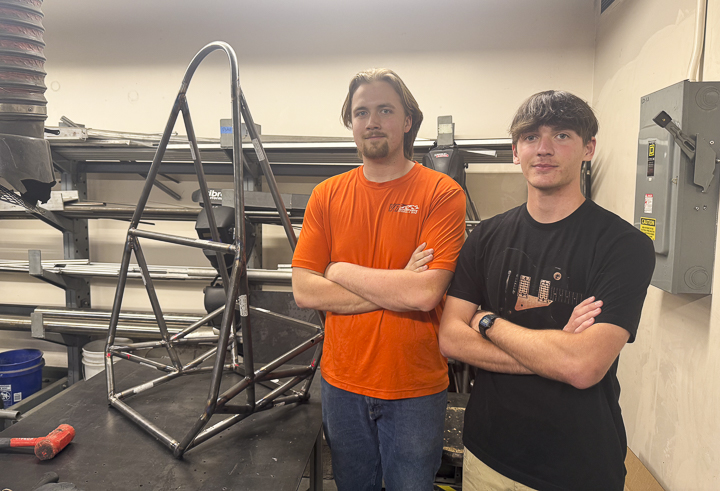

Hank Pete, the Formula SAE ‘26 and ‘27 Chassis Lead, shed light on navigating the challenges of the competition and what it takes to keep Virginia Tech’s team at the forefront. “Our team runs a two-year cycle, so the ‘26 car was designed through the last year and is being built this year through 25 fall, 26 spring,” said Pete. “While that’s happening, the 27 car is also in tandem, being designed as the 26 is being built.”

It’s not as simple as working on one car at a time. The team is constantly balancing design and manufacturing, contributing to multiple projects at once. Since the ‘26 and ‘27 competition builds include internal combustion and electric variants, the team is essentially working on four different vehicles at once while modifying previous models for testing platforms. “We’re consistently having meetings trying to ensure that everyone stays on the same page,” said Pete. “It’s so much project management. That’s the one thing in engineering that they never really go over a lot. We’re consistently trying to get this car funded, make sure that our timelines align, and make sure that the weather is permitting [for testing].”

In the midst of all the hecticness and challenges, the team’s end goal is to achieve first place. Competition consists of three categories, including technical inspection, static analysis, and dynamic testing. Technical inspection ensures that the vehicle can operate safely in real-world conditions. There are three static events which involve a design portion, business presentation, and cost analysis. The dynamic events are where the vehicle is pushed to its limits, testing acceleration, cornering, speed/handling, and endurance.

“I feel confident. We got 15th last year [nationally] and are ranked 25th internationally out of about 370,” said Pete. With last year’s competition bringing unexpected hiccups, Pete believes the team can improve on last year’s placement. “The hope is a top 10 finish this year. Last year, because of some issues with testing and overall verification, the aerodynamics package was basically rendered useless by the time of testing. So we were the highest placed team without an aero package on our car.”

While the main focus is competition ‘26, the team is constantly reviewing past performances and learning how to best approach new vehicle design and development. Nick Carneiro, the suspension lead for competition ‘27, discussed the importance of intentional design and applying past experiences to improve at competition. “Leading a team through design, we start off the first semester mainly brainstorming and researching, looking at data from the previous years, seeing what could be improved, what could stay the same,” said Carneiro. “That’s the end goal, we are designing this car to win. What will make us the most points that we missed last year, right?”

These combined efforts across sub-teams to put the team in a position to succeed have created a strong community for Virginia Tech’s team. There is a collective passion that brings its members together even when presented with rigorous tasks and unexpected hurdles. “It’s definitely a labor of love, right? At the end of January, I had a week where I pulled 110 hours in the lab,” said Pete. “This is the stuff that I’m really passionate about. I get to be on the cutting edge of technology that college students are able to work on.”

The team also acts as a second home for many of its members and serves as a place to make new friends over shared passions. “I made most of my friends on this team coming into tech,” said Carneiro. “There are new faces every year, new freshmen, new sophomores that come in, and we all have common interests in building this race car. It’s a massive community. We all have to support each other.”

The Virginia Tech Motorsports Formula SAE team is hoping for a stellar performance at this year’s competition in May. Along the way, the team will continue to overcome challenges, push the boundaries of Formula development, and build their community.